Quality Control

The quality of our products and raw materials is very important to us. Quality control guarantees compliance with specifications and the highest product quality in terms of organoleptic, chemical, and microbiological parameters. All our products receive batch-specific certificates, which contain the physical and chemical properties as well as the microbiological status.

Chemical and Physical Analysis

Our raw materials and sales products undergo vigorous testing methods to guarantee that only products of the highest quality leave our premises. Therefore, compliance with pre-defined product specifications is verified for every batch using established analytical methods.

The following list shows a few of the methods we conduct in our laboratory:

- Nitrogen determination

- Water content

- UV/VIS

- Polyphenol analysis

- Color scale

- HPTLC

- HPLC

- Sieve analysis

- Peroxide value

- Iodine value

- Acid value

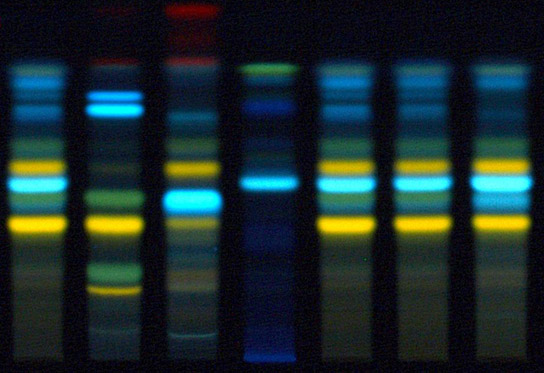

HPTLC fingerprint of HerbaGlow® NRG. Our Full-Spectrum Mild Extraction process includes the extraction of all solvent-soluble molecules.

Microbiology and Hygiene

In regards to microbiological quality control, our products are tested for safety in terms of bioburden. Determination of aerobic bacteria, yeasts and molds, as well as the absence of specific pathogenic microorganisms is carried out by means of validated microbiological cultures and screening procedures. The microbiological methods and specifications are prepared according to the guidelines recommended for cosmetics referring to the ISO 21149:2006 norm and the European Pharmacopoeia (Pharm. Eur.).

In addition, hygiene measures and process water control are essential elements in our production cycle. Based on Standard Operation Procedures (SOP), we monitor these parameters closely and respond accordingly to deviations. The application of good hygiene practice and hygiene awareness are internally promoted by regular training courses.

- Quality Management

- Quality Policy

- Quality Control

- Regulatory Affairs